The context

Natural gas market is experiencing an exciting growth pushed by the increase in global energy demand. Furthermore, natural gas is replacing coal for electricity generation and is a candidate as fuel for maritime and road transportation due to its cleaner combustion. The reduced carbon dioxide emissions with respect to other fuels make natural gas the perfect solution waiting for the readiness of the renewable energy technologies.

One of the axes of growth for natural gas market is LNG. As a general rule of thumb, LNG becomes more economically convenient than transport in pipelines at approximately 3200 km onshore and 1600 km offshore. Furthermore, LNG represents a flexible solution, capable of adapting to an always growing and changing market. Small and micro scale LNG technologies are also designed as a potential solution for the exploitation of stranded reserves and associated gas.

The challenge

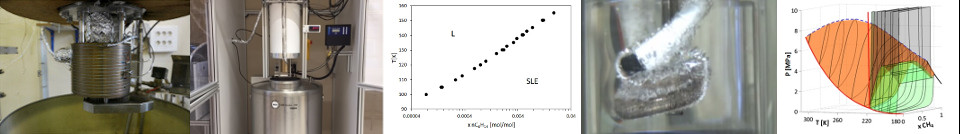

The rapid growth of LNG market compares companies with the major problem of crystallization of impurities in the natural gas liquefaction process. Because of the low temperature necessary to liquefy natural gas, risk of crystallization of impurities (carbon dioxide, aromatics, water, sulfur compounds, etc.) is one of the major technical problems to be considered in natural gas liquefaction process design.

Formation of solids in LNG production process coats heat exchangers and fouls process equipment. Massive solid deposits can plug the pipes creating major safety problems, like the risk of breakage or explosions. Solids can also create safety and operation problems during expansion processes and accidental or programmed gas release.

Formation of solids in LNG production process coats heat exchangers and fouls process equipment. Massive solid deposits can plug the pipes creating major safety problems, like the risk of breakage or explosions. Solids can also create safety and operation problems during expansion processes and accidental or programmed gas release.

A large number of impurities belonging to different chemical families can be found in natural gas. Few data are available concerning the solubility limits of these impurities in natural gas components. At the same time, predictive models prove not to be accurate in representing the available solubility data. The lack of experimental data and the inaccuracy of models result then in a great uncertainty on the specifications for the natural gas feeding the liquefaction trains.

This obliges the companies to adopt big safety margins in the liquefaction processes, causing the increase of energy consumption, oversized design of the pre-treatment units, and loss of profit in the LNG sale.

Are current specifications too much restrictive? Do the existing specifications reflect the actual freeze out limits? Which is the impact of allowing 100 ppm or 120 ppm of CO2 instead of 50 ppm in the cost of gas treatment (the same question can be asked about the other impurities)? Larger margins in impurity concentration will probably lead to less energy consuming purification processes and then lower environmental impact and higher margins in LNG sale.

The partners of the first phase (January 2018 – June 2021)

The partners of the second phase (July 2021 – June 2024)

Looking for more information? Download the flyer of the project : CTP JIP LNG flyer